OUR PRODUCTS

Here you can learn more about FIBC's

Flexible Intermediate Bulk Containers

FIBCs (Flexible Intermediate Bulk Containers) Or Bulk bags, Jumbo bags, Super sack, Big bag, or Tonne bag, are versatile and durable packaging solutions designed to handle and transport bulk materials efficiently. Constructed from woven polypropylene or polyethylene, these bags offer exceptional strength while remaining flexible, making them ideal for various industries.

Our FIBCs offer extensive customization options, allowing tailoring to precisely match your unique requirements for handling, transporting, and storing materials.

Types of Flexible Intermediate Bulk Containers

A flexible intermediate bulk container is undoubtedly the most favoured and cost-effective packaging solution for storing and transporting bulk materials like granules, chemicals, and pharmaceuticals.

However, with varying material requirements, sizes, and designs, selecting the appropriate bulk container bags can pose a daunting challenge. That’s why, as manufacturers of FIBCs, we provide a wide range of solutions tailored to cater to various small to large-scale industries.

These FIBC variations encompass Type A, B, C, and D, which differ in their electrostatic properties and grounding requirements. Each FIBC type performs well in specific industries, and comprehending their distinctions can assist industries in making informed choices concerning safety and environmental protection.

FIBC Bags Types

STANDARD

STANDARD FOUR-LOOP BAG

With our STANDARD BAG , simplicity meets reliability, ensuring your materials are handled with utmost ease and efficiency, setting the standard for seamless logistics.

Standard big bags comprise all big bag types with a standard construction of bottom, four walls and four corner loops and with no special purpose.

Big bags are produced for every customer according to his individual requirements.

things that help us to produce the perfect FIBC that fit your industry is to know :

– The goods you want to fill in your FIBC.

– The measurement the FIBC should have.

– Weight the FIBC should carry

– The simple way for you to lift your FIBC

– Top and bottom FIBC type

If you have special requests or need a special designs check FIBC Bags Specifications OR contact our sales team

FIBC Bags Specifications

Filling option

Discharging option

Loops option

FORMSTABLE

FORMSTABLE BIG BAGS (Q-BAGS)

Shaping the Future of Space Efficiency. Where innovation meets practicality, these formstable marvels not only secure your materials but also optimize storage, maximizing every inch of available space.

Formstable Big Bags, often referred to as Q-Bags, designed with internal structures or features that maintain their shape, even when they are partially filled, emptied, or stacked.

These bags are especially advantageous in industries where space optimization, stability during transportation, and efficient storage (up to 25%) of formstable big bags compared to standard big bags.

If you have special requests or need a special designs check FIBC Bags Specifications OR contact our sales team

Big bags are produced for every customer according to his individual requirements.

things that help us to produce the perfect FIBC that fit your industry is to know :

– The goods you want to fill in your FIBC.

– The measurement the FIBC should have.

– Weight the FIBC should carry

– The simple way for you to lift your FIBC

– Top and bottom FIBC type

FIBC Bags Specifications

Filling option

Discharging option

Loops option

VENTILATED

VENTILATED BIG BAGS

Enhanced Airflow, Superior Performance

Our ventilated big bags are designed to optimize airflow, ensuring your products stay fresh and well-ventilated during storage and transportation

Ventilated big bags, are large, flexible containers used for storing, handling, and transporting various materials. These bags are designed with ventilated panels or features that allow airflow through the bag while maintaining the structural integrity needed for bulk handling.

The ventilation in these bags is crucial for products that require airflow to prevent moisture buildup, maintain freshness, or regulate temperature. Items like agricultural produce, firewood, seeds, or other goods that are sensitive to moisture or need adequate airflow benefit from ventilated big bags.

The design of these bags typically includes mesh panels, perforations, or other breathable materials integrated into the bag’s structure, allowing air to circulate. Ventilated FIBC helps in preserving the quality of the contained goods by reducing the risk of spoilage, mold, or other issues associated with inadequate airflow.

If you have special requests or need a special designs check FIBC Bags Specifications OR contact our sales team

Big bags are produced for every customer according to his individual requirements.

things that help us to produce the perfect FIBC that fit your industry is to know :

– The goods you want to fill in your FIBC.

– The measurement the FIBC should have.

– Weight the FIBC should carry

– The simple way for you to lift your FIBC

– Top and bottom FIBC type

FIBC Bags Specifications

Filling option

Discharging option

Loops option

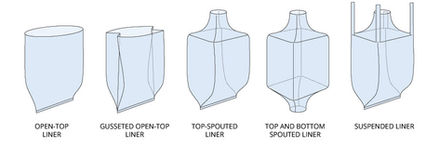

WITH INLINERS

BIG BAGS WITH INLINERS

Dual Protection, Enhanced Preservation

Our big bags with inliners offer a double layer of protection, safeguarding your goods from external elements while preserving their quality from within

Big bags with inliners include an additional inner liner within the bag’s structure. These inliners are often made from various materials such as polyethylene or polypropylene and are designed to provide an extra layer of protection to the contents stored within the FIBC.

The purpose of these inliners is to offer an added barrier against moisture, contaminants, or fine particles that might otherwise penetrate the main body of the big bag. They act as a secondary enclosure, preventing leakage, spillage, or the ingress of external elements that could compromise the quality or integrity of the materials being stored or transported.

Big bags with inliners are commonly used in industries dealing with sensitive or fine materials that require an extra level of protection. They are particularly useful for products like powders, granules, chemicals, food ingredients, pharmaceuticals, and other items that need to be shielded from moisture, dust, or potential contaminants.

If you have special requests or need a special designs check FIBC Bags Specifications OR contact our sales team

Big bags are produced for every customer according to his individual requirements.

things that help us to produce the perfect FIBC that fit your industry is to know :

– The goods you want to fill in your FIBC.

– The measurement the FIBC should have.

– Weight the FIBC should carry

– The simple way for you to lift your FIBC

– Top and bottom FIBC type

FIBC Bags Specifications

Filling option

Discharging option

Loops option

UN BAGS

UN BAGS

Certified Confidence in Every Load

Experience the pinnacle of safety with our UN-certified big bags, meeting stringent international standards for the secure handling of hazardous goods.

UN big bags, also known as UN Certified (FIBCs), are designed and certified to transport hazardous materials safely. The United Nations (UN) sets specific standards and regulations for the transportation of dangerous goods, including substances that are flammable, toxic, corrosive, or pose other risks.

These bags are constructed according to stringent guidelines outlined in the UN’s recommendations. They undergo rigorous testing and evaluation to ensure they can withstand the challenges associated with transporting hazardous materials. UN big bags are typically used for substances like chemicals, powders, or other materials that require containment and transportation in compliance with international safety regulations.

The certification involves various aspects such as the bag’s design, construction materials, labeling, and performance under different conditions (like stacking, impact, and drop tests). UN-certified FIBCs are assigned specific codes based on the type of hazardous material they are designed to contain and transport

If you have special requests or need a special designs check FIBC Bags Specifications OR contact our sales team

UN SIGN AND CODE

FIBC Bags Specifications

Filling option

Discharging option

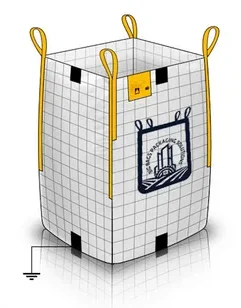

CONDUCTIVE

CONDUCTIVE BIG BAGS

Empowering Safe Handling

Our conductive bags empower safe handling, mitigating static risks to preserve the integrity of your electronic components and delicate materials during transit and storage.

Conductive big bags are indispensable in industries reliant on the safe handling and transportation of sensitive materials. These specialized containers act as a shield against the damaging effects of static electricity, preventing electrostatic discharge that could jeopardize the integrity, quality, or safety of stored or transported goods. By dissipating static charges, conductive big bags safeguard sensitive electronic components, volatile chemicals, pharmaceuticals, and other static-prone materials from potential damage. Their usage ensures compliance with rigorous safety standards, mitigates fire and explosion risks, and maintains product quality, ultimately reducing costly losses and ensuring operational efficiency. Conductive big bags are not just containers; they are an assurance of protection, reliability, and adherence to essential safety measures in diverse industries where static control is paramount

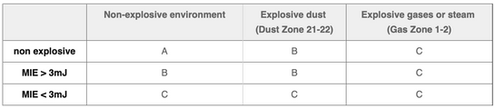

there are two situations that bear danger:

Explosive materials – When explosive materials are filled into big bags the usage of conductive big bags is determined by the minimum ignition energy of the materials.

Explosive Environment – An explosive environment can be given by dust, gases or steam. The highest danger is given when the explosive environment consists of gases or steam.

Which type of Conductive FIBC do I need?

If you have special requests or need a special designs check FIBC Bags Specifications OR contact our sales team

CONDUCTIVE INLINERS

Big Bags with Inliners can also be constructed as Type B or Type C. They are constructed with special conductive Inliners.

LABELLING CONDUCTIVE BIG BAGS

Conductive big bags are labeled with an yellow extra label which contains some relevant information.

TESTING CONDUCTIVE BIG BAGS

We are measuring both breakdown voltage and conductivity of the fabric and the finished Type C big bags.

Big bags are produced for every customer according to his individual requirements.

things that help us to produce the perfect FIBC that fit your industry is to know :

– The goods you want to fill in your FIBC.

– The measurement the FIBC should have.

– Weight the FIBC should carry

– The simple way for you to lift your FIBC

– Top and bottom FIBC type

FIBC Bags Specifications

Filling option

Discharging option

Loops option

ONE / TWO LOOPS

ONE / TWO LOOPS BIG BAGS

Looping Innovation, Handling Simplified

Innovative looping designs redefine ease of handling – our one- and two-loop big bags simplify operations, enhancing your logistics effortlessly.

One- and two-loop big bags stand as indispensable solutions in the logistics and transportation landscape, offering a multitude of advantages. These bags revolutionize cargo handling with their convenient looping systems, providing optimal lifting points that streamline loading, unloading, and transportation processes. Their versatility shines through diverse applications, accommodating a wide spectrum of materials and sizes, making them adaptable across industries. By distributing weight evenly and ensuring stability during transit, they guarantee secure transportation while optimizing storage space through stackability. Customizable configurations cater to specific handling needs, and their durable construction ensures longevity and cost-effectiveness through repeated use. Ultimately, these bags redefine efficiency, reliability, and convenience in material transport, making them a cornerstone choice for businesses seeking seamless logistics operations.

USAGE

Mostly used for packing fertilizer (e.g. Urea) and in the chemical industry, but is also used for packing various types of grains, seeds, briquettes, pellets, cement and other materials.

INLINER

Usually is a PE Inliner of 60my to 90my thickness placed inside the one and two loop big bags. They protect the goods from moisture and from product leakage.

If you have special requests or need a special designs check FIBC Bags Specifications OR contact our sales team

CARRYING WEIGHT

The Safety work load (SWL) of one and two loop big bags can be between 500kg and 1500kg with a safety factor (SF)of 5:1 (single trip) or 6:1 (multi trip). For fertilizers often 500kg, 600kg, 750kg or 1000kg is used. One and two loops big bags can be furthermore constructed as UN bags.

Big bags are produced for every customer according to his individual requirements.

things that help us to produce the perfect FIBC that fit your industry is to know :

– The goods you want to fill in your FIBC.

– The measurement the FIBC should have.

– Weight the FIBC should carry

– The simple way for you to lift your FIBC

– Top and bottom FIBC type

FIBC Bags Specifications

Filling option

Discharging option

FIBC Bags Specifications

Lifting Options

Experience effortless material handling with our FIBC bulk bags featuring versatile lifting options. From cross-corner loops to corner and single loops, our bags offer adaptable lifting mechanisms suitable for various equipment. Engineered for safety and efficiency, these lifting configurations ensure secure and balanced handling, optimizing your industrial workflow.

Document Pocket

Ensure efficient documentation and easy access with our FIBC bulk bags equipped with document pockets. Featuring secure pockets for invoices, labels, or paperwork, these bags streamline inventory management and shipment tracking. Designed for convenience and compliance, our document pockets offer a practical solution for organizing and safeguarding essential paperwork during transportation and storage.

Discharging Options

Enhance your material handling efficiency with our FIBC bulk bags offering diverse discharging options. Whether it’s through spouts, skirts, or bottom openings, our bags facilitate controlled and efficient material discharge. Designed for precision and convenience, these discharging options ensure seamless flow and precise handling of bulk materials, tailored to your operational needs.

SWL and SF

Prioritize safety and reliability with our FIBC bulk bags, engineered with specified safety workload and safety factor options. Compliant with industry standards, our bags are designed to handle designated workloads with a defined safety factor, ensuring secure containment and transport of bulk materials. Trust in our bags’ strength and adherence to safety regulations, providing peace of mind for your operational needs.

Filling Options

Streamline your operations with our FIBC bulk bags offering versatile filling options. Our bags feature adaptable top designs, including open tops, spouts, or duffle closures, ensuring easy and efficient filling. Engineered for convenience and reliability, these filling options provide seamless integration with your production processes, enabling hassle-free and controlled material loading.

Fabric

Discover tailored solutions with our FIBC bulk bags, offering diverse fabric options and GSM specifications. Our range includes various fabric compositions and GSM choices, ensuring durability and suitability for different load capacities. From lightweight to heavy-duty fabrics, find the perfect combination for your specific material handling requirements.

Printing

Elevate your brand and streamline logistics with our customizable FIBC bulk bags featuring versatile printing options. From company logos to product details, our bags offer high-quality, custom printing, enabling clear identification and enhanced branding. Tailored to meet your specifications, our printing solutions ensure efficient communication and seamless tracking throughout the supply chain.